Quality Coordinator

My position as the Quality Coordinator covers the overall coordination of activities, communication, and inspections within the Quality Department. I regularly communicate vendor issues, part deviations and part improvements with our vendors and we work to error-proof these issues as they arise.

I worked for Kalas Manufacturing as a Quality Technician performing in-process inspections and maintaining their calibration and ISO / TS 16949 auditing systems. Kalas Manufacturing produces wire cable assemblies and harnessing for large companies such as John Deere, Caterpillar, Case New Holland, and Freightliner.

I started at Seakeeper November 2014.

When I started in November 2014, I was hired as a Quality Inspector. I performed in-process inspections for our machining group. It was great exposure to be able to learn from within in a fast-paced machine shop. We are now focused on looking at more purchased parts these days to accommodate our increasing sales demand.

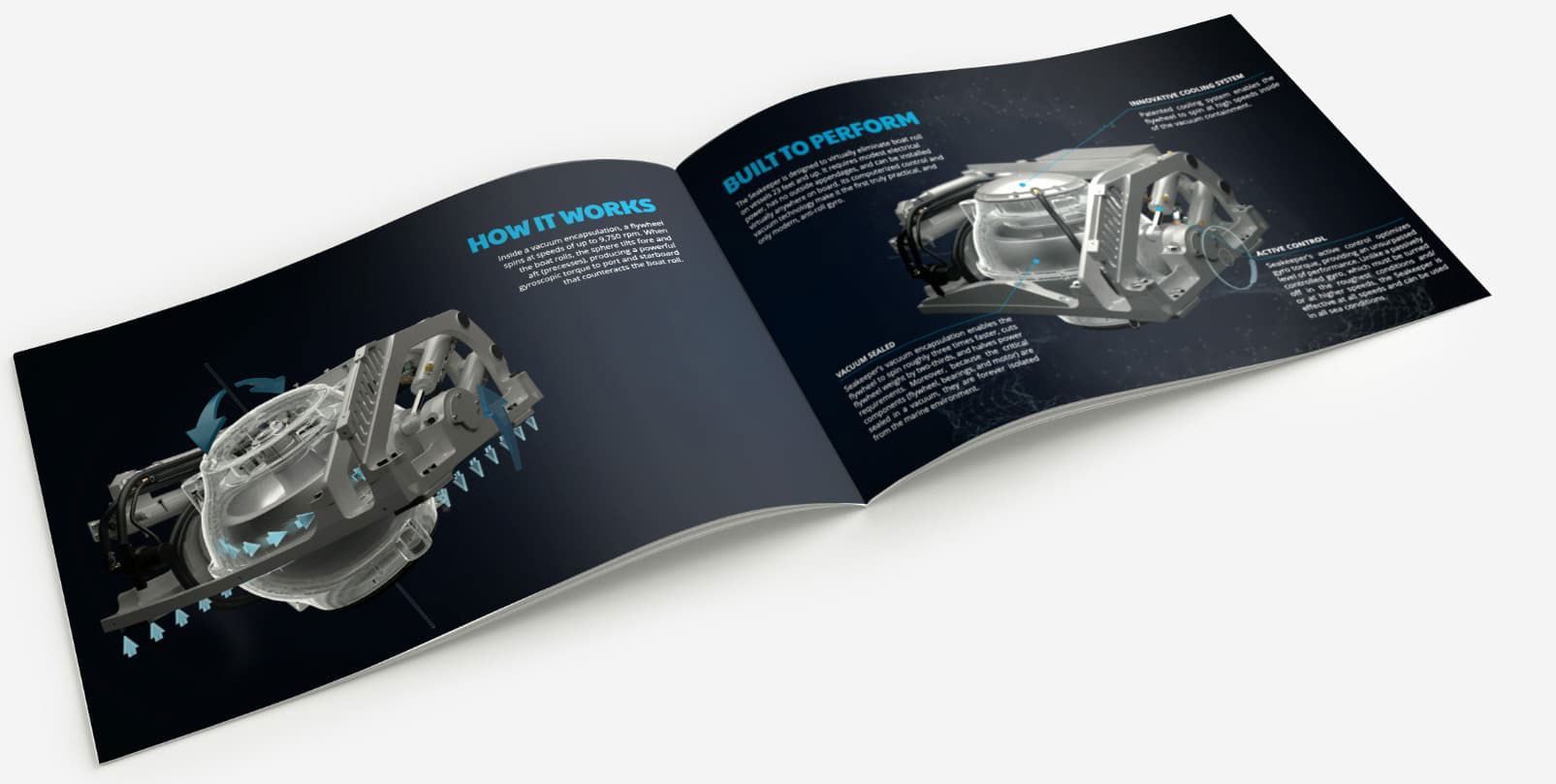

I think one of the more interesting jobs I have seen was the product launch of the Seakeeper 1. The gyro is such a compact, intricate unit, which made it interesting for inspection because we initially were not used to checking such small parts. Seeing these during crating inspection is still fascinating.

The knowledge and career growth that Seakeeper has afforded me has been a wonderful opportunity in my life.

I really enjoy the state-of-the-art products we make. I’m a boat owner and have loved boating for years. It’s exciting what Seakeeper brings to the table for the boating world.

The most challenging part of my role is part rejections. There are many processes that need to take place in a short period of time in order to keep production going, inventory correct, and the vendor notified to correct outgoing product.

Being part of the Seakeeper team requires hard work, consistency, and most importantly dedication. Seakeeper has been a great company to work for.

I’d have to say Joe Levan. In the 5 years that I worked with Joe, I was able to learn a wealth of machine shop inspection knowledge from him. He trained me on our CMM & DCC machines that we regularly use. Joe always put in the extra effort to get the job done the right way and I hope to have gained that work ethic from him.

I believe that any level of job you perform you should do it to the best of your ability. If you take the time, you can learn anything.

I volunteer in my free time at the Mid Atlantic Air Museum in Reading, PA, painting various World War II aircrafts. Recently, I have been given the opportunity to paint their Northrop P61 Black Widow night bomber as the restoration continues. This airplane crashed in New Guinea in 1944 and was recovered in 1980 by MAAM. This eventually will be the only one to fly in the world.

Thank you Seakeeper for the opportunities and continued support.