Controls Manufacturing Engineer

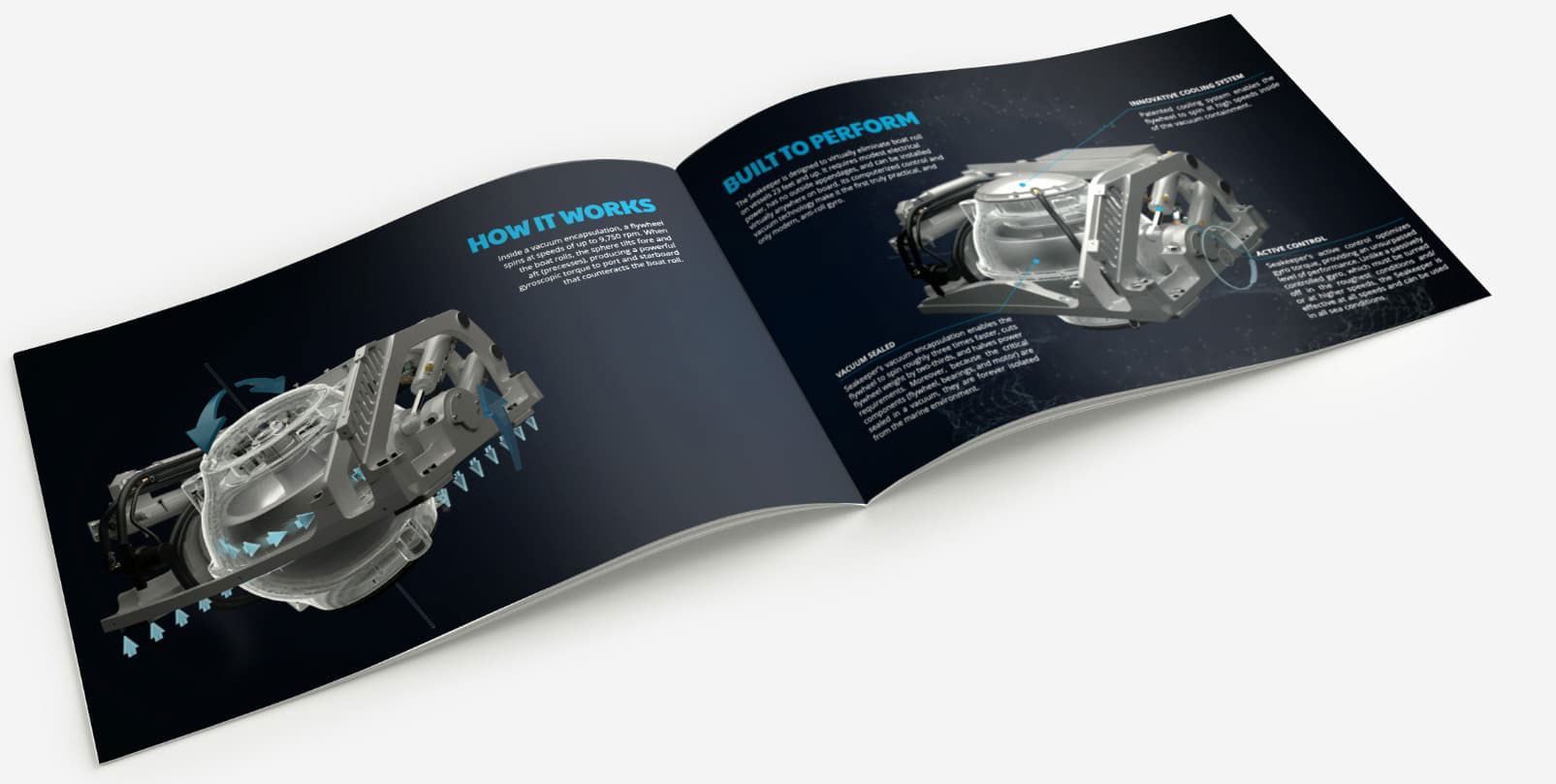

I design and maintain a variety of Seakeeper’s production equipment for gyro manufacturing in Pennsylvania and manage the release process for new production gyro software. My every day involves work as both an Electrical Engineer and a Software Controls Engineer to solve ongoing and upcoming production issues and implement improvements in production.

I worked as an Automation Engineer for water treatment plants for both municipal fresh water and wastewater. I worked with water utility companies and municipalities in eastern Pennsylvania to propose and implement electrical automation and SCADA solutions to their existing and new sight locations.

June 2019

I’ve had three roles in the almost four years I’ve been with Seakeeper. I worked on the Seakeeper Ride’s actuator system when it was in the Alpha and Beta stages, which is now a highly successful product, now managed in Florida. I worked with the Production Engineering Department for the extensive move of all Seakeeper’s custom electrical production equipment to the new facility in Leesport, Pennsylvania, which was able to be completed with little downtime.

I have witnessed Seakeeper undergo record-breaking annual revenues, increase the number of gyros sold, and navigate through Covid-19’s shutdown. Over my years at Seakeeper, I have gained pride in the company’s work, often promoting Seakeeper’s amazing products to friends and family. And I look forward to successful years to come here at Seakeeper.

One of the most interesting jobs I have had with Seakeeper was when I traveled to Schaeffler Inc. in South Carolina to commission a testing fixture that I helped design and build for the Seakeeper Ride actuator.

Personally, I find having learned enough at Seakeeper that I now answer electrical and software problems in Seakeeper’s gyro production has been my largest accomplishment here at Seakeeper. It is a rewarding experience when I can listen to the issues and safety concerns of people here at Seakeeper and can address those issues.

Ever since I saw Seakeeper’s website while going to college in Vermont, I wanted to work at Seakeeper and be a part of the industry-changing products Seakeeper manufactures. The part I like the most about working at Seakeeper is showing new people what Seakeeper is and how incredible their gyro and Ride systems are

Engineers working in Production Engineering and across my whole team are tasked with multiple ongoing projects and problems that need immediate attention to keep production running. These tasks happen all at once. While managing priorities can be challenging, successfully managing one’s time, making the ideal compromises, and rescheduling current projects to address immediate issues are important. These steps help ensure projects are not forgotten and that improvements to Seakeeper’s production equipment are being fully implemented.

Listen first because Seakeeper is full of smart people to learn from. Remember what you learned in school because you never know when you will need it. And find activities outside work you enjoy.

Mike Gallagher had the greatest impact on my time at Seakeeper. He is an incredibly smart engineer, and working with him showed me a lot about product development and good practices for controls engineers to follow.

“Listen first, speak second.” Prioritizing listening first over talking gives the greatest chance of learning something new and improves your ability to be of the most help.

I grew up in Vermont on a small family farm that was part of our 350 acres. Our town only had 10% of its roads paved, and the rest were dirt. I moved to Pennsylvania after graduating college, where I currently live 47 miles from work at Seakeeper’s Leesport Facility.